Contract Manufacturing: Metal Stamping Services

Metal Stamping Overview

New Standard is a leading contract manufacturer with expertise in progressive and deep draw metal stamping. Whether you require small parts or large complex parts, our market leading stamping capabilities allow us to deliver stamped components with optimal reliability and precision. To meet diverse industry needs, we can accommodate production volumes from 1 to 1,000,000 using materials such as stainless steel, copper, aluminum, and pre-painted steel.

Ready To Start Your Next Project?

Why Metal Stamping?

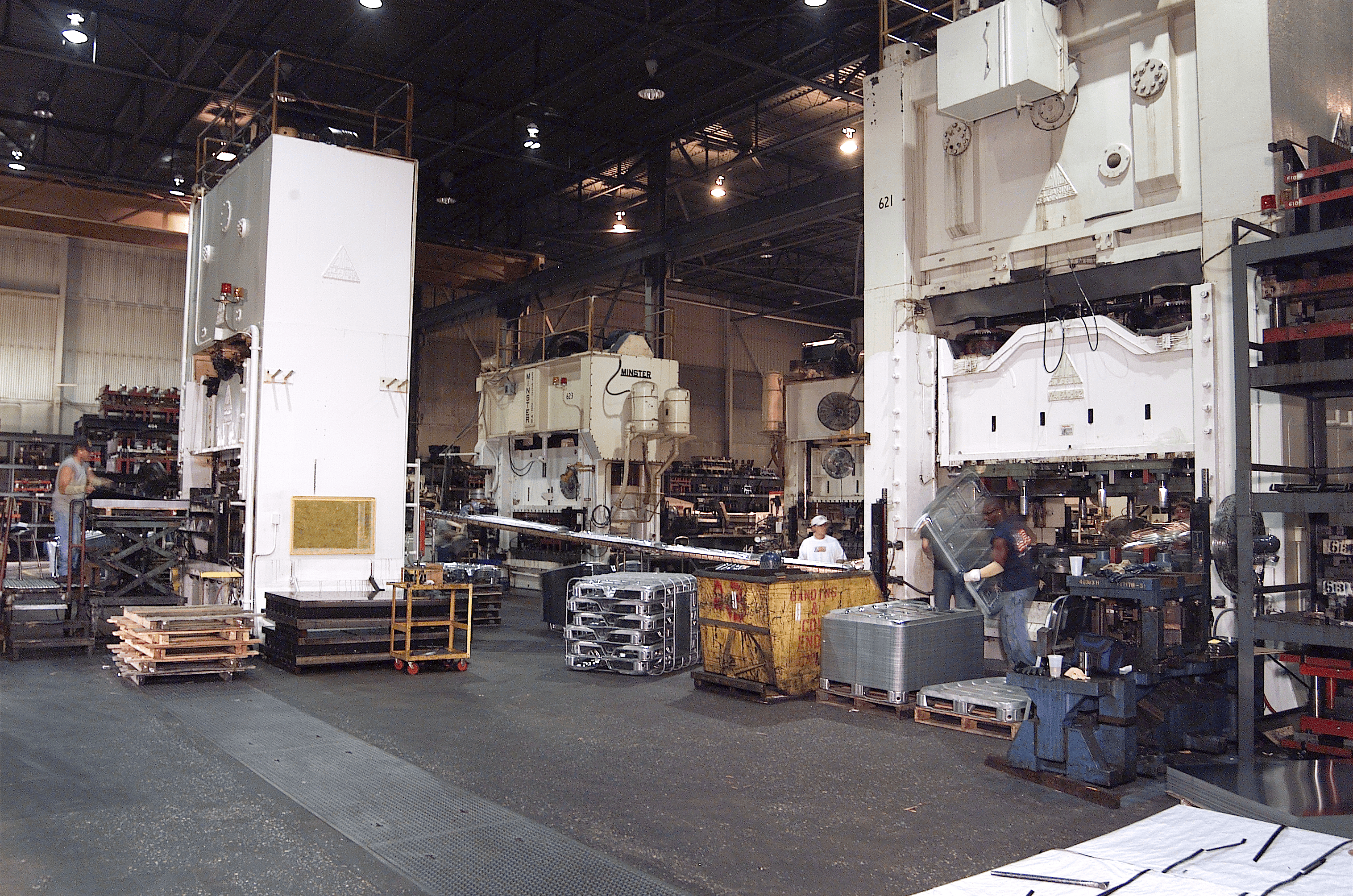

In metal stamping, sheet metal in coil or blank form is fed into a stamping press. Tooling mounted in the press strikes the metal with significant force, forming it into the desired shape or profile. Common stamping operations include flanging, embossing, coining, bending, blanking, and punching.

At New Standard, metal stamping is at the core of our capabilities. As an ISO 14001, ISO 9001, and AWS D1.1 and D1.3 certified company, we can produce stampings for applications including power generation, fuel dispensing, agricultural equipment, commercial and residential HVAC, class 8 trucks, heat sensors, bearing retainers, and flapper valves.

We start every project with a technical, detailed, and collaborative process to ensure a precise and timely product launch. When you partner with us for your stamping needs, you’ll benefit from the following:

- Improved efficiency: Metal stamping is rapid. Depending on the size and complexity of the design and material thickness, our stamping presses can create hundreds or thousands of parts per hour. This is extremely valuable for high-volume orders and ensures fast turnaround times for large range of quantities.

- High precision and accuracy: We use precision-designed tooling and dies to ensure a high degree of accuracy for every project. Our durable dies are built for minimal wear over time, so parts have little variation. Because tooling is created for each stamping project, parts meet all tolerances and dimensional specifications.

- Versatility: We can stamp materials in different widths and thicknesses. This flexibility allows us to stamp varying sized parts, as well as simple, complex, or intricate designs.

Our Metal Stamping Capabilities

New Standard’s metal stamping capabilities include:

- Range: Our stamping presses range from 5 to 2,700 tons, with a maximum bed size of 262 inches long by 72 inches wide.

- Heavy-tonnage stamping: We are one of the few family owned stamping companies to offer extremely high-tonnage, large bed stamping services.

- Advanced stamping technology: We offer both progressive die and deep draw stamping, with custom-engineered dies.

- Mixed-mode manufacturing: Metal fabrication services are also available, including fiber laser cutting, welding, press braking, and brazing.

- Scalability: We can scale our metal stamping process to meet large-volume orders or tailor solutions to meet our customers production needs.

- Investment in technology: We invest in the latest stamping equipment and advanced manufacturing technology to provide the latest materials and process innovations.

Material and Industry Expertise

New Standard brings expertise with many types of materials and designs to customers in many industries. We offer a comprehensive selection of materials in coil and blank forms, including specialized materials, to meet your unique requirements.

Our experienced team of engineers, designers, and technicians serves OEMs and their suppliers in industries including agriculture, HVAC, construction equipment, packaging, power generation, heavy truck, and aerospace.

Engineering and Design Support

Our engineers and designers work closely with you to optimize your design for cost-effective material selection, manufacturability, and end-use functionality. We’re there from concept to prototyping to final production.

Why Choose New Standard for Metal Stamping

New Standard offers a wide range of stamping capabilities, engineering and design support, metal fabrication, welding, assembly, and kitting to deliver a seamless solution for your manufacturing needs. Contact us to speak with a specialist about your next metal stamping project.

Case Studies

Oil Coolers

Learn how New Standard’s vertical integration and supply chain expertise helped an OEM increase output and quality for their oil coolers.

Crossmembers

Learn how New Standard helped a customer overcome previous supply chain issues to produce high-quality steel crossmembers for their Class 8 trucks.

Fuel Dispenser Frames

New Standard provides diverse industries with optimized product solutions focused on design and cost improvement. Learn how we partnered with a long-time customer to develop new fuel dispenser frames.