Overview

At New Standard Corporation, we provide leading original equipment manufacturers (OEMs) with vertically integrated contract manufacturing services and high-quality products and assemblies. For more than 80 years, our family-owned business has been committed to providing product and process solutions that emphasize efficiency, quality, and collaboration while driving growth and profitability for our customers.

Targeted Capabilities

New Standard offers a comprehensive range of contract manufacturing and value-added services tailored to meet our clients’ individual needs. With vast experience across industries, we serve commercial and industrial markets ranging from agriculture and mining equipment to power generation and heavy trucks. Our core competencies include:

- Engineering and design for manufacturability (DFM)

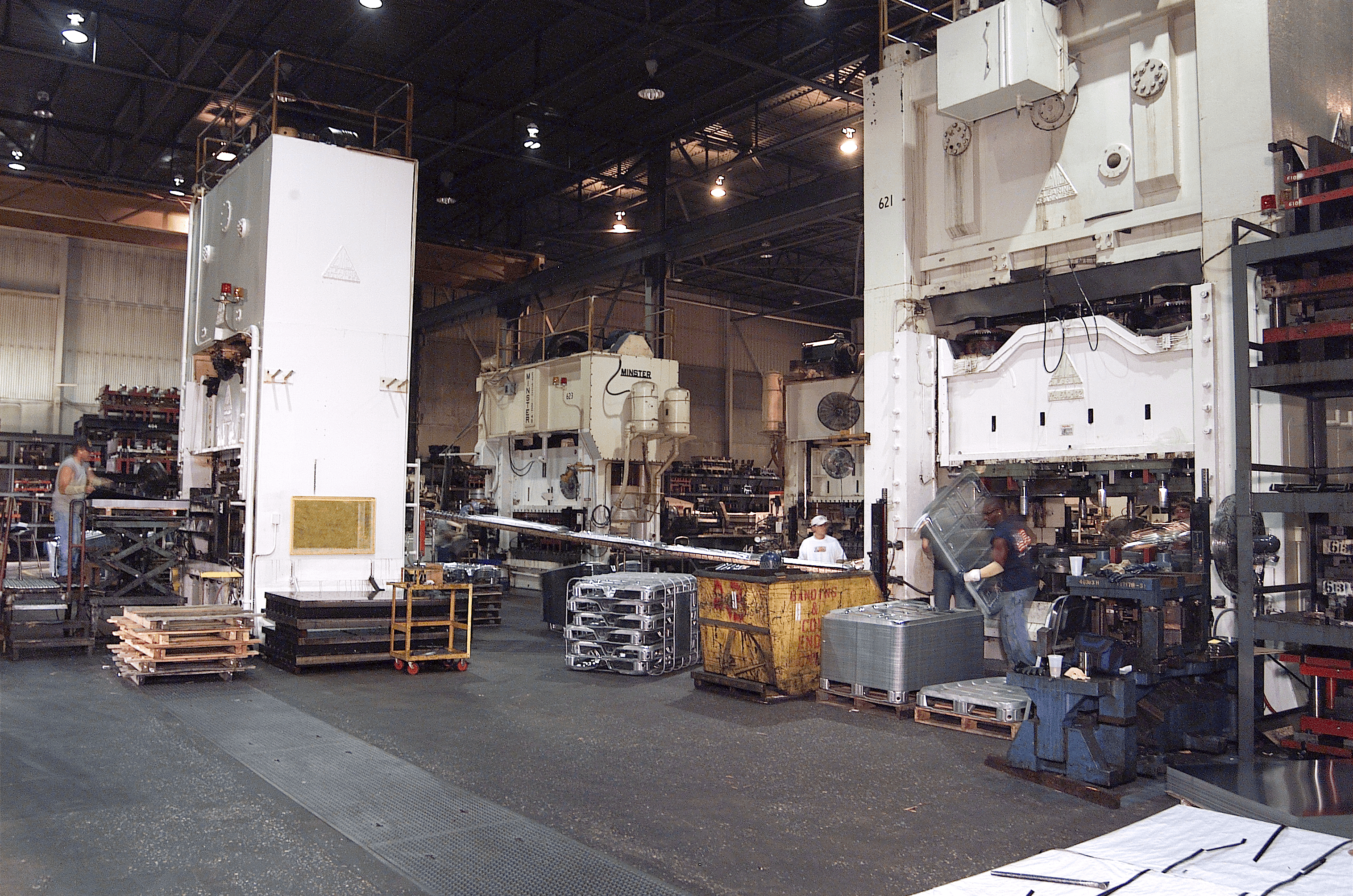

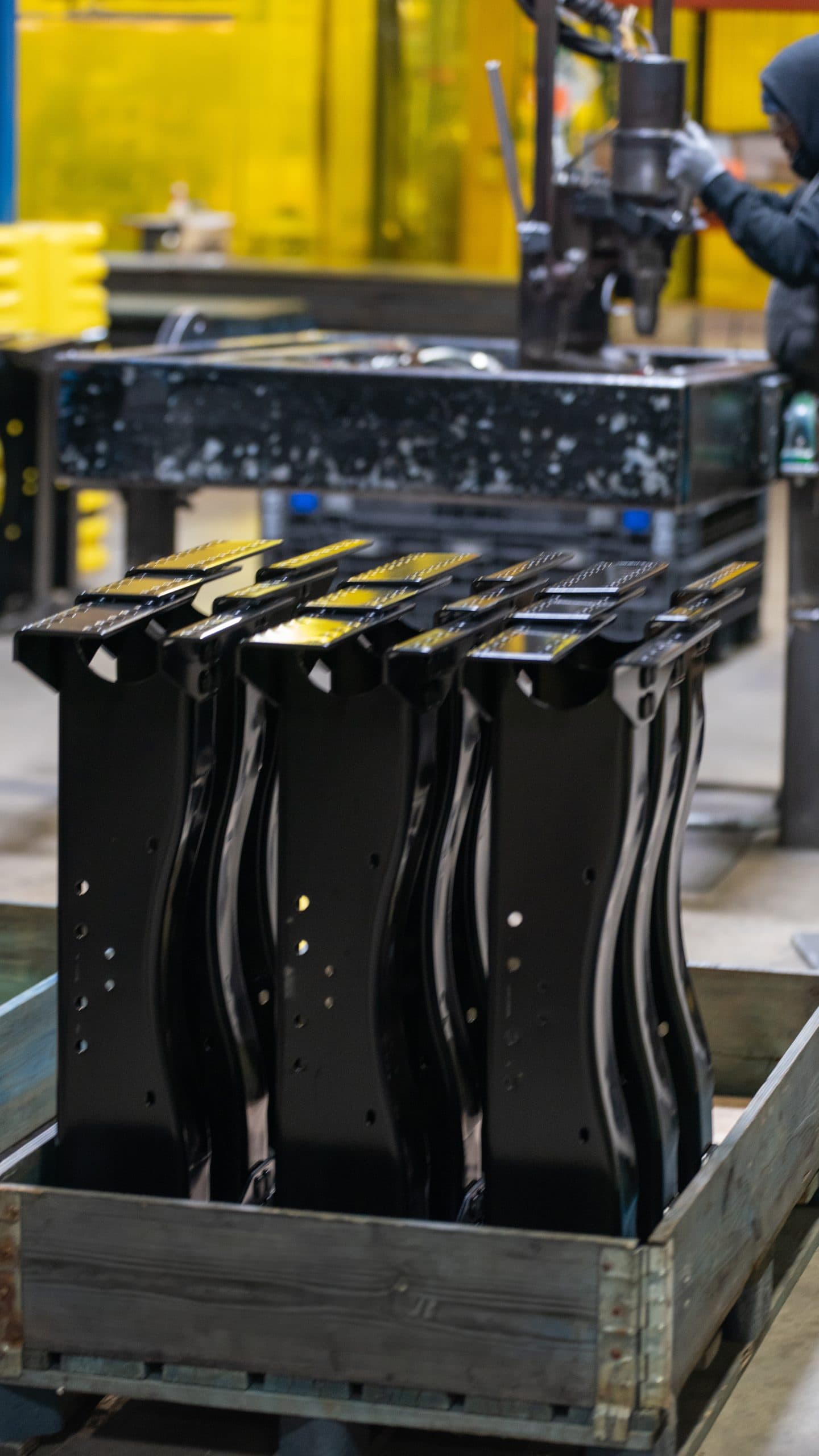

- Metal stamping and fabrication

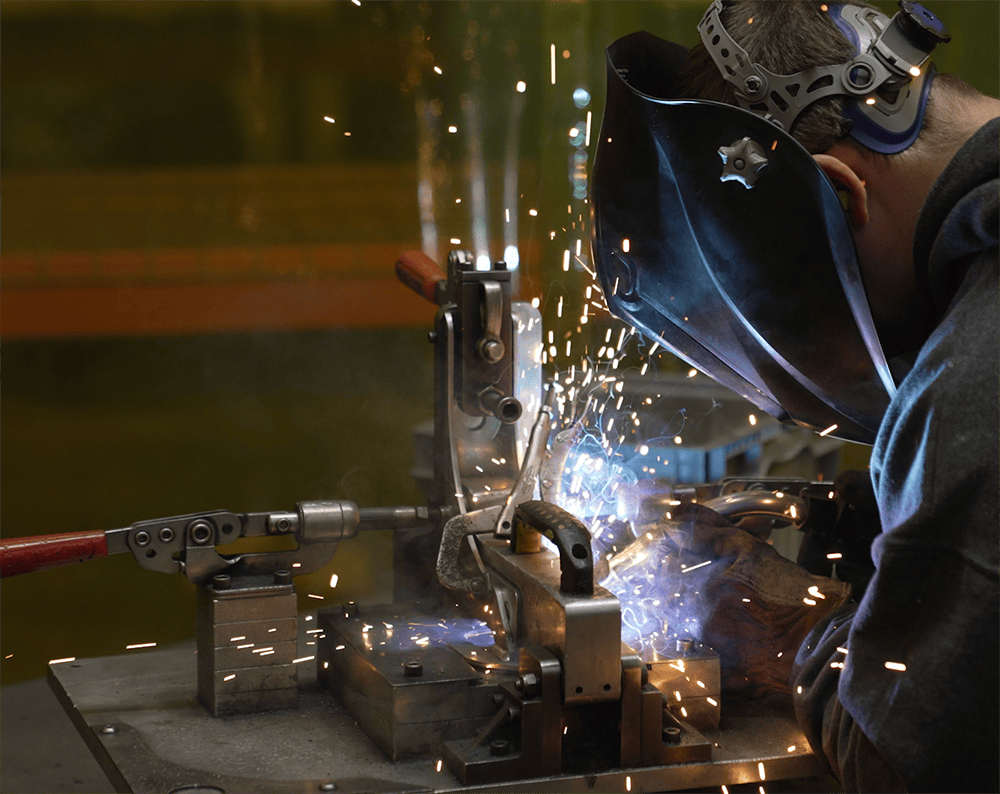

- Assembly and welding for complex or large products

- Supply chain management and global procurement

Our vertically integrated design and development capabilities allow us to review both products and processes for quality at every stage while also pinpointing areas where we can improve efficiency or cost. We employ a dedicated Customer Action Team to manage engineering processes and focus on quality control starting with the design phase.

New Standard offers a comprehensive range of contract manufacturing and value-added services tailored to meet our clients’ individual needs. With vast experience across industries, we serve commercial and industrial markets ranging from agriculture and mining equipment to power generation and heavy trucks. Our core competencies include:

- Engineering and design for manufacturability (DFM)

- Metal stamping and fabrication

- Assembly and welding for complex or large products

- Supply chain management and global procurement

Our vertically integrated design capabilities allow us to review both products and processes for quality at every stage while also pinpointing areas where we can improve efficiency or cost. We employ a dedicated Customer Action Team to manage engineering processes and focus on quality control starting with the design phase.

At New Standard, we have the bandwidth and scalable solutions to handle everything from low- to high-volume production runs. Our team operates equipment ranging from press brakes to advanced fiber lasers in our well-equipped 471,000 square feet of facility space spread over four locations. With a focus on operational efficiency, we also incorporate automation as part of our goal to Accelerated Production Timeline and deliver high-quality goods within the desired timeframe. Our operational capacity, vertical integration, and geographical spread give us the agility to deliver speed to market, even for challenging projects.

We can execute and manage complex assembly projects to create heat transfer components, power generation modules, heavy highway HSLA chassis assemblies, laundry pedestals, stainless steel tub components, and everything in between. We are committed to quality in our complex assembly and supply chain management processes, as evidenced by our ISO9001 certification.

Partnering with New Standard is a step toward improved supply chain resiliency and control. Our sophisticated supply chain contributes to project success, enabling us to quickly respond to clients’ specific requirements and changes in demand for materials, parts, and products. Through global procurement, our operational footprint, and our vast experience in supply chain management, we can help you resolve even complex challenges and streamline operations.

We understand the importance of investing in our clients’ success. We continually make new investments in production equipment, tooling, and technologies to meet clients’ unique needs as well as boost efficiency and productivity. Additionally, our team is the most important asset we have, so we invest in the best engineering staff available to provide high-quality products and services.

By integrating our services under one in-house operation, we excel at turning clients’ product concepts into reality. Part of our ability to do that is our collaborative design for manufacturability (DFM) approach to product design. When developing a product, our talented in-house engineering team reviews all aspects of a product’s design, to optimize the manufacturability of the specific product and to provide suggestions to reduce cost while maintaining high quality standards, and make suggestions on ways to reduce costs and improve the ease of manufacturing without sacrificing quality.

New Standard helps customers solve complex challenges through proactive and collaborative partnerships, optimized designs, and innovative, cost-effective solutions. Our commitment to operational excellence, willingness to invest in clients’ needs, and unsurpassed capabilities in DFM, contract manufacturing, assembly, and supply chain management make us the ideal strategic partner for diverse industries.

Contact us today to learn how New Standard can help support your application through industry-leading solutions

Ready To Start Your Next Project?

Time to Market

At New Standard, we have the bandwidth and scalable solutions to handle everything from low- to high-volume production runs. Our team operates equipment ranging from press brakes to advanced fiber lasers in our well-equipped 471,000 square feet of facility space spread over four locations. With a focus on operational efficiency, we also incorporate automation as part of our goal to reduce time to market and deliver high-quality goods within the desired timeframe. Our operational capacity, vertical integration, and geographical spread give us the agility to deliver fast market response, even for challenging projects.

Complex Assembly

We can execute and manage complex assembly projects to create heat transfer components, power generation modules, heavy highway HSLA chassis assemblies, laundry pedestals, stainless steel tub components, and everything in between. We are committed to quality in our complex assembly and supply chain management processes, as evidenced by our ISO/TS 16949 certification.

Sophisticated Supply Chain

Partnering with New Standard is a step toward improved supply chain resiliency and control. Our sophisticated supply chain contributes to project success, enabling us to quickly respond to clients’ specific requirements and changes in demand for materials, parts, and products. Through global procurement, our operational footprint, and our vast experience in supply chain management, we can help you resolve even complex challenges and streamline operations.

Willingness to Invest

We understand the importance of investing in our clients’ success. We continually make new investments in production equipment, tooling, and technologies to meet clients’ unique needs as well as boost efficiency and productivity. Additionally, our team is the most important asset we have, so we invest in the best engineering staff available to provide high-quality products and services in everything we do.

Engineering Resources and DFM Expertise

By integrating our services under one in-house operation, we excel at turning clients’ product concepts into reality. Part of our ability to do that is our collaborative design for manufacturability (DFM) approach to product design. When developing a product, our talented in-house engineering team reviews all aspects of a product’s design, working with you to optimize it, determine the ideal manufacturing processes to efficiently create it, and make suggestions on ways to reduce costs and improve the ease of manufacturing without sacrificing quality.

Offloading Case Study

A world leader in kitchen equipment and appliance production turned to New Standard when product demand was exceeding their manufacturing capacity. The goals of the outsourcing project were to:

- Quickly free up facility space

- Manufacture stainless steel tub components in high volumes

- Produce sub-assemblies

- Fulfill just-in-time (JIT) delivery needs

- Reduce costs

To achieve this seamlessly for zero downtime, we invested in a 120,000-square-foot manufacturing facility to integrate the client’s equipment, as well as new washers, presses, roll form lines, and an $8 million hydraulic tandem line.

By outsourcing production to our team, the client realized over $1 million in annual savings, gained significant facility space, and benefited from the improved product quality that the New Standard team provided in its daily shipments. Our two-year participation in their product development cycle and the project’s results evidence New Standard’s fabrication and assembly capabilities, project management skills, willingness to invest, and more.

Case Studies

Oil Coolers

Learn how New Standard’s vertical integration and supply chain expertise helped an OEM increase output and quality for their oil coolers.

Crossmembers

Learn how New Standard helped a customer overcome previous supply chain issues to produce high-quality steel crossmembers for their Class A trucks.

Fuel Dispenser Frames

New Standard provides diverse industries with optimized product solutions focused on design and cost improvement. Learn how we partnered with a long-time customer to develop new fuel dispenser frames.

Begin Your Journey With New Standard

New Standard helps customers solve complex challenges through proactive and collaborative partnerships, optimized designs, and innovative, cost-effective solutions. Our commitment to operational excellence, willingness to invest in clients’ needs, and unsurpassed capabilities in DFM, contract manufacturing, assembly, and supply chain management make us the ideal strategic partner for diverse industries.

Contact us today to learn how New Standard can help support your application through industry-leading solutions.