Oil Coolers Overview

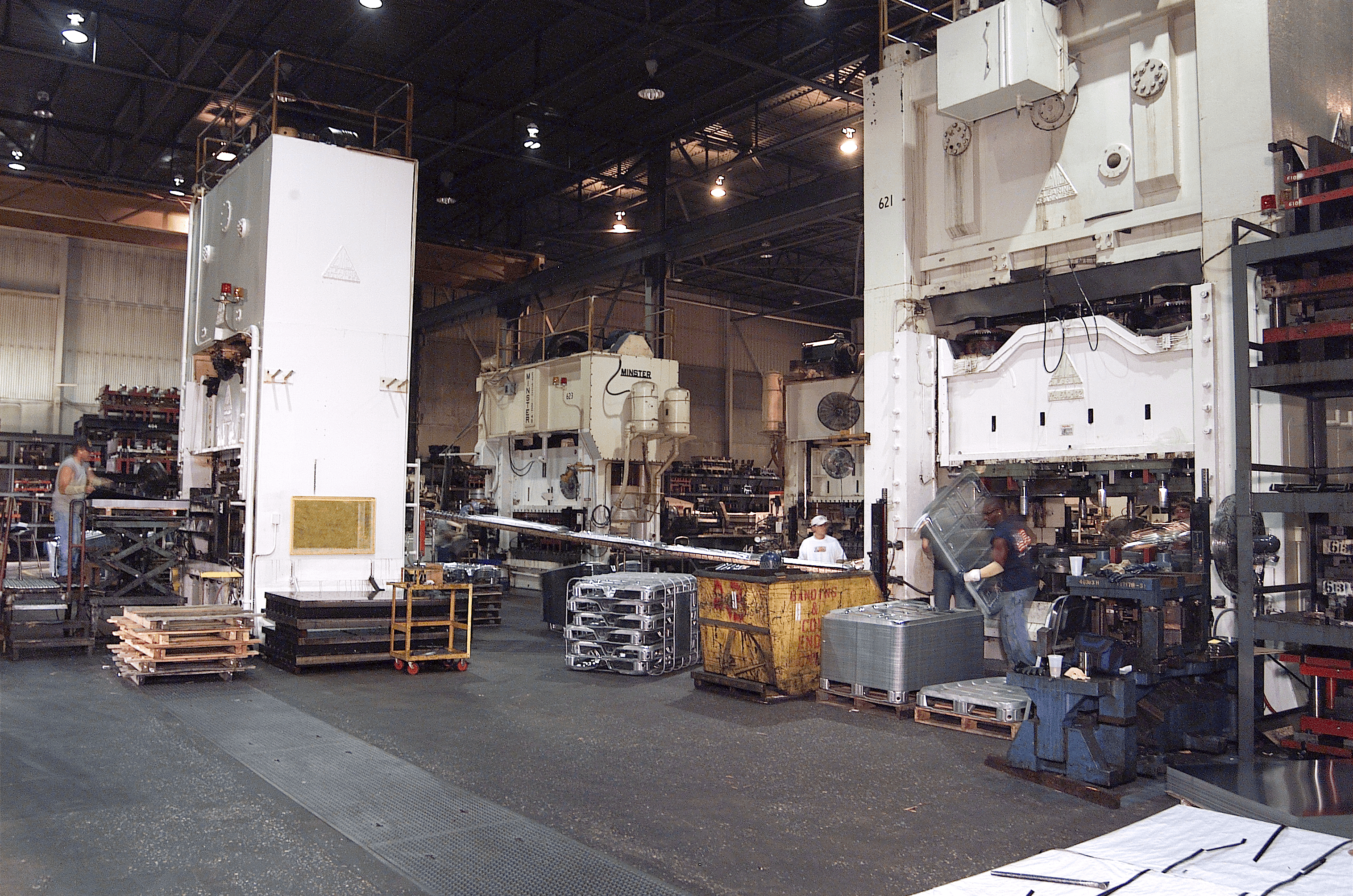

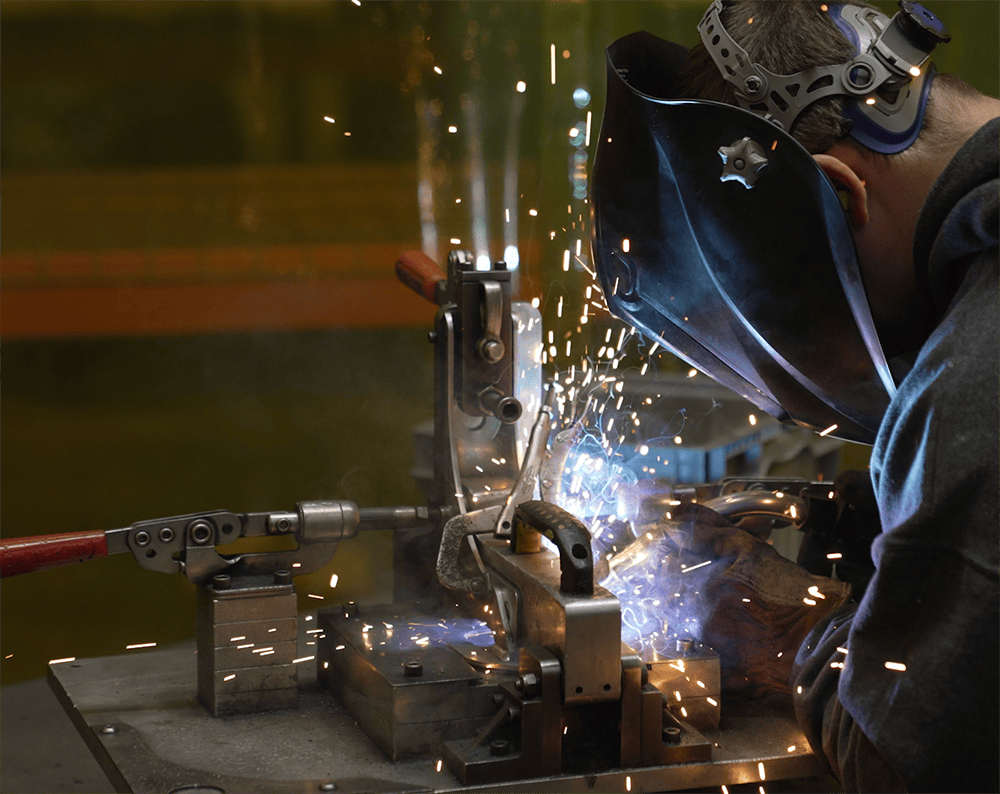

As a leading vertically integrated contract manufacturer, New Standard Corporation serves OEMs across diverse industries with in-house capabilities, including metal stamping, fabrication and complex assembly. We also work with a long list of trusted suppliers to expand our capabilities and deliver full-service solutions for our valued customers.

Our services and solutions apply to a variety of industries, including:

Construction

Construction Agriculture

Agriculture Mining

Mining HVAC

HVAC Heavy Trucks

Heavy Trucks Power Generation

Power Generation Packaging and Distribution

Packaging and DistributionRead this case study to learn how we delivered a complex solution for a long-term customer in the construction and mining industry, demonstrating our engineering and design for manufacturability (DFM) expertise.

Ready To Start Your Next Project?

The Challenge: Oil Coolers

This customer needed reliable oil coolers with highly particular specifications. These parts ranged from five inches in diameter by 10 inches in length to 12 inches in diameter by 54 inches in length, with a weight range of 20 to 250 pounds. Our customer’s existing supply chain showed single points of failure, which meant that if there was a problem in just one area, they would face delays or wouldn’t be able to meet production goals. Their supply chain was also centered around a single location, which created capacity issues when demand increased.

The oil coolers also needed to meet various standards, including:

- Pressure decay testing

- Flow testing

- Thermal testing

- Cleanliness testing

- Other customer-specific standards

For 30 years, New Standard had been producing just the internal cooling tube bundles for the OEM’s oil coolers. To solve the customer’s capacity issues, New Standard stepped in with our vertical integration expertise to help them diversify their supply chain, converting it from fixed cost to variable cost. This meant reevaluating every component of the oil cooler, which could be very complex, comprising as many as 300 SKUs per part.

The Solution: A New High-Capacity Facility

New Standard introduced supply chain resiliency by building out the product’s supply chain and developing a new high-capacity facility for the customer. Given the large scope of the project, we took a multiphase approach to build the new facility with new capabilities, hiring the client’s employees as subject matter experts for the oil coolers. This allowed for effective knowledge transfer for the product and new processes during the transition.

This process entailed:

- Investing in new equipment for duplicate capacity: New Standard ran the product while the OEM ran the product to reduce supply gaps.

- Gradually moving production elements, including equipment, from the old facility to the new facility.

- Nearly 10 months of outfitting the new facility, followed by a year of transferring products and machinery to the new facility. In the process, New Standard managed the supply chain from the beginning to end and took full responsibility for the customer’s product quality.

By streamlining the customer’s supply chain and expanding capabilities, New Standard successfully outfitted and moved the customer’s facility within 2 years. The results were increased production and greater product quality.

A general manager from our customer who oversaw this project said that our handling of this product transfer was the best and one of the biggest he had ever experienced in his career. This large-scale project set new standards of transparency and collaboration.

The Result: A Significant Boost in Efficiency and Productivity

The development of transfer to the new facility resulted in immense success for the customer. New Standard’s expertise in supply chain resilience led the customer to significantly increase outputs and product quality while reducing overall manufacturing costs. The new high-capacity facility helped the customer achieve an output increase of over 50%.

Our ability to outfit facilities with new equipment while keeping up with efficient production is key to the success of many of our OEM clients. To learn more about how our vertically integrated contract manufacturing solutions can serve your organization, contact us today.

Case Studies

Oil Coolers

Learn how New Standard’s vertical integration and supply chain expertise helped an OEM increase output and quality for their oil coolers.

Crossmembers

Learn how New Standard helped a customer overcome previous supply chain issues to produce high-quality steel crossmembers for their Class 8 trucks.

Fuel Dispenser Frames

New Standard provides diverse industries with optimized product solutions focused on design and cost improvement. Learn how we partnered with a long-time customer to develop new fuel dispenser frames.