Contract Manufacturing - High-Complexity Assembly

High-Complexity Assembly Overview

At New Standard Corporation, we specialize in the complex. For intricate assembly projects involving diverse parts and requiring precision accuracy, our experienced team will provide high-value, high-complexity assembly as part of our comprehensive contract manufacturing services. New Standard delivers turnkey, vertically integrated project solutions with in-house fabrication and assembly capabilities for clients in industries ranging from construction and mining to consumer products.

Ready To Start Your Next Project?

Advanced Electromechanical Assembly Capabilities

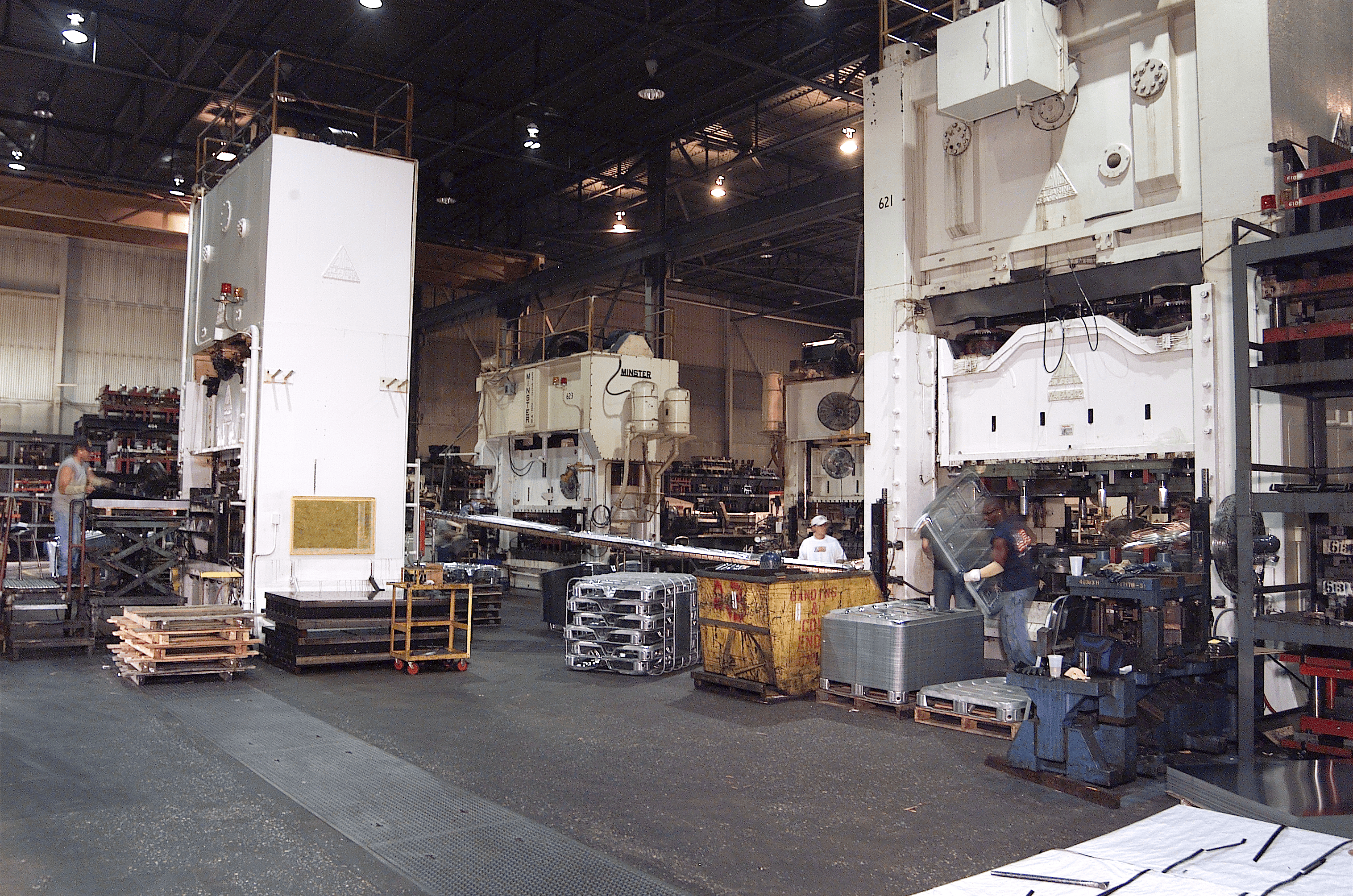

New Standard offers in-house electromechanical assembly services in our facilities across the United States. With a focus on efficiency, we specialize in complex parts and precise assemblies to give you the peace of mind that your final products will meet your specifications and quality expectations.

Our value-added assembly solutions are ideal for everything from heat transfer parts and complex power generation modules to heavy highway HSLA chassis assemblies. We can utilize plastic in your assemblies or add electronic or motorized parts to fabricated or welded metal assemblies.

When you partner with New Standard, your project will be supported by:

- A team of over 350 trained personnel with a commitment to world-class quality

- Four domestic facilities comprising more than 400,000 square feet of design, development, manufacturing, and space for large assemblies.

- Versatile fabrication equipment, including presses that can provide 5 to 2,700 tons of force, overhead cranes, and specialty welding machinery.

We invest in our team and our equipment so that we can provide cutting-edge services and precision results for complex projects.

Turnkey Solutions With Vertically Integrated Operations

Our services don’t start or end with high-level assembly. Instead, we provide comprehensive, vertically integrated services so you can turn to a single vendor for all of your contract manufacturing and electromechanical assembly needs. Through vertical integration, we provide more reliable, consistent, and cost-effective services than you can receive when developing a supply chain of multiple vendors. Working with a vertically integrated supplier allows for rigorous quality control from sourcing to shipment of a finished product.

Our vertically integrated services include:

- Product design and collaboration through development, including engineering support and design for manufacturing (DFM) services

- Value add value engineering (VAVE) to minimize costs

- Raw material sourcing and procurement

- Identifying new suppliers

- Supply chain management, with the ability to onboard and manage existing suppliers

- Contract manufacturing

- Welding and complex electromechanical assembly

- Quality control (QC) and product testing

- Product packaging and shipping

Quality Assurance and BOM Management

As products become more specialized and their designs more intricate, quality control becomes increasingly important. At New Standard, our team will collaborate with you to ensure your assemblies meet your design parameters with precision. We set high quality standards, ensuring accuracy through every facet of component assembly.

This starts with meticulous Bill of Materials (BOM) management. By reviewing and managing an up-to-date list of all assembly components, subassemblies, drawings, documentation, and other related details necessary to source and construct a complex assembly, our team ensures that we can fabricate and assemble your products right the first time.

Case Studies

Oil Coolers

Learn how New Standard’s vertical integration and supply chain expertise helped an OEM increase output and quality for their oil coolers.

Crossmembers

Learn how New Standard helped a customer overcome previous supply chain issues to produce high-quality steel crossmembers for their Class 8 trucks.

Fuel Dispenser Frames

New Standard provides diverse industries with optimized product solutions focused on design and cost improvement. Learn how we partnered with a long-time customer to develop new fuel dispenser frames.

Get in Touch With New Standard's High-Complexity Assembly Experts Today

New Standard is a leading provider of vertically integrated, complex assembly services for electromechanical products. By partnering with our company, you gain access to over a century of experience and a team committed to exceptional quality, efficiency, affordability, and customer service. Contact us today to learn more about how New Standard can help bring your assembly project from concept to reality.