How OEMs Can Avoid the High Costs of Supply Chain Delivery Disruptions

Supply chain delivery delays can disrupt every level of an OEMs operations. In today’s procurement landscape, there exist a myriad of challenges that can adversely impact your operations. However, OEMs can proactively mitigate these risks by strengthening their supplier networks with supply chain companies that are committed to operational excellence and resilience. The following showcases the challenges confronted by today’s procurement organizations and the value of building a network of suppliers dedicated to your success.

Understanding Supply Chain Challenges for OEMs

The first step in navigating potential supply chain delays is identifying the specific obstacles that impact your industry or company. Consider which of these following challenges are impacting your company’s operations. Then, use the “Supplier Checklist” to assess if your suppliers have the mitigation strategies in play in order to protect you from each challenge.

Material Shortages and Capacity Constraints

Procurement specialists face significant challenges when suppliers miss deliveries due to material shortages or capacity constraints that were not anticipated or communicated in advance. These disruptions can lead to production delays, increased costs, and strained relationships with internal stakeholders and customers. Mitigating this risk requires a high degree of transparency and engagement on the part of the supply chain.

Supplier Checklist

- Highly reliable raw material supplies with purchasing power and long-standing relationships with key sources

- Comprehensive capacity planning at the supplier’s operations and visibility of supply constraints at lower levels in the supply chain

- Routine reviews with the supplier and their key supply lines to assess capacity and material resiliency

Logistical Delays

Logistical delays can result from miscommunications, poor software system integration, shipping and transportation delays, and even increased import regulations or port confusion. Recent examples include the UK's exit from the European Union and disruption during the COVID-19 pandemic. Smaller but more commonplace issues can arise from warehousing problems, poor inventory management within OEMs or their suppliers, and general infrastructural issues.

Supplier Checklist

- Efficient and agile EDI/ERP systems to ensure routine demand signals are met and immediate response to order collaboration for urgent order modifications.

- Accessible and experienced account management to provide immediate, real-time support for any unanticipated disruptions to order fulfillment.

Geopolitical Reasons

Trade disputes, new tariffs, and international conflict or unrest can significantly disrupt supply chain dynamics. OEMs may encounter unpredictable delays or face the possibility of skyrocketing costs in order to ensure timely production. Many OEM’s are pursuing an ‘In Region, For Region’ supply strategy to mitigate geopolitical uncertainty. For this to be successful, your supply chain needs the sophistication and experience to pivot to meet these needs.

Supplier Checklist

- Experience in global sourcing and tariff implications to mitigate tariff exposure or build supply redundancy

- Local sourcing to insulate your company from geopolitical uncertainty and import tariffs

Supplier Financial Instability / Operational Failure

Suppliers under prolonged financial stress are likely to suffer operational failures and poor performance, leading to delivery delays, quality problems, degrading collaboration and transparency or loss of key personnel. Knowing the financial conditions of your supply base and anticipating problems are essential to maintaining the health of your delivery performance.

Supplier Checklist

- Open book financial collaboration

- History of strong financial performance and a willingness to reinvest in their company

- Strategic mindset and ability to articulate their strategic direction and actions

- Comprehensive IT/Cybersecurity capability and maintains third party audit certifications

Visibility, Communication, and Collaboration

End-to-end supply chain management is an ongoing challenge for OEMs in every industry. There can be communication siloes between distributors and suppliers, miscommunications to or from stakeholders, and even language or time zone barriers. OEMs without advanced end-to-end communication solutions that centralize their supply chain processes can suffer.

Supplier Checklist

- Demonstrated willingness for collaboration and transparency

- Accessible account management and full engagement of executive leadership to demonstrate the importance of the relationship and commitment to the OEM’s success

For procurement professionals seeking supply chain solutions, find more successful strategies in our ebook.

The Benefits of a Strategic Partnership with New Standard Corporation for your Manufacturing Supply Chain

There are many reasons to trust New Standard Corporation as a supply chain partner. We are a vertically integrated, Tier 1 contract manufacturer, and we support OEMs with +98% on-time delivery for critical components. From our York, PA, Emingsville, PA, and Rocky Mount, NC locations, we provide our customers with reliably high rates of on-time fulfillment. And, we can demonstrate each and every Checklist item listed above to ensure the success of your operations and mitigate your supply chain disruptions.

Why New Standard Corporation?

Supply chain delivery delays significantly disrupt OEM operations and profits in every industry. New Standard Corporation provides reliable, integrated, on-time contract manufacturing and delivery so those disruptions have minimal effect on our customers’ business. Contact us today to learn how we can supply parts, complex sub-assemblies, and finished goods to make your business more resilient in any economic or geopolitical situation.

Related Posts

November 14, 2024

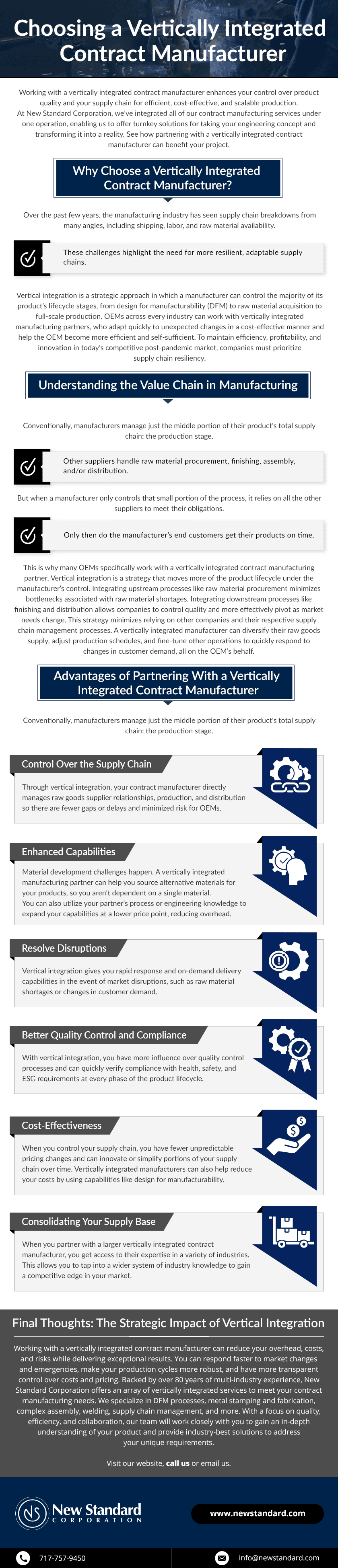

How to Choose a Vertically Integrated Contract Manufacturer

Working with a vertically integrated contract manufacturer enhances your…